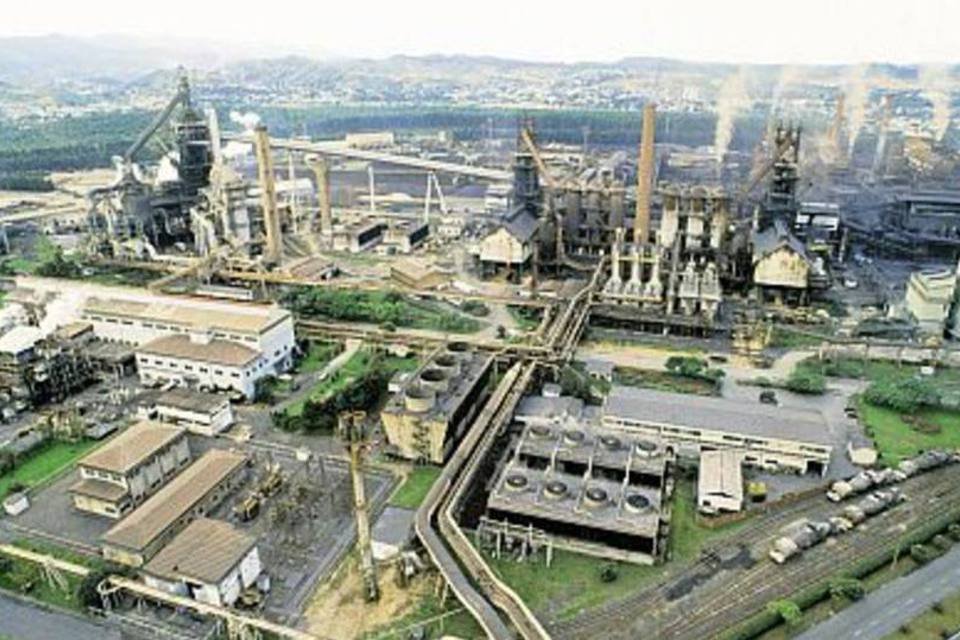

What is the significance of the large-scale steel production facility in Ipatinga, Brazil? A leading player in South America's steel industry, it shapes the economic landscape of the region.

The steel mill in Ipatinga, a major industrial hub in Minas Gerais, is a comprehensive facility focused on the production and processing of steel. This complex encompasses diverse stages, from raw material processing to the creation of finished steel products. The mill's output serves a variety of industries, including construction, manufacturing, and infrastructure development, highlighting its crucial role in the local economy.

This facility's importance extends beyond regional impact. Its large-scale operations create considerable employment opportunities, driving economic growth in the surrounding areas. The mill also plays a key role in supplying steel to national infrastructure projects, fostering national development. Furthermore, the environmental sustainability efforts of the operation are essential, demonstrating a commitment to responsible industrial practices in a crucial sector.

Moving forward, the article will delve into specific aspects of the facility, including its history, production processes, economic impact, and environmental considerations.

Usiminas Ipatinga

Usiminas Ipatinga represents a crucial steel production hub, impacting Brazilian and regional economies. Understanding its multifaceted nature is key to appreciating its significance.

- Production capacity

- Steel variety

- Employment creation

- Infrastructure support

- Economic growth

- Environmental impact

- Global market presence

The production capacity of Usiminas Ipatinga directly correlates with its ability to supply the steel needed for infrastructure projects and manufacturing. The variety of steel produced, from specific types tailored to automotive needs to more general grades for construction, reflects a diverse customer base. Employment opportunities generated foster community development. The mill's products support essential infrastructure, boosting economic growth. Environmental impact assessments and sustainable practices are vital components of modern industrial operations. Finally, the mill's market presence in national and global markets demonstrates its economic importance and competitiveness. These interconnected aspects contribute to the overall impact of Usiminas Ipatinga within Brazil's industrial landscape. For instance, the facility's steel products might be incorporated into bridges, high-rises, or even auto parts, demonstrating its far-reaching effects.

1. Production Capacity

The production capacity of Usiminas Ipatinga is a defining characteristic, directly impacting its overall contribution to the Brazilian steel industry. A substantial production volume is essential to meet the demands of national and international markets. This capacity is measured not only in tons of steel produced but also in the variety and types of steel products available. A high production capacity allows the facility to serve a broader range of industries and fulfill diverse customer needs. For example, high production capacity enables Usiminas Ipatinga to consistently supply steel for major infrastructure projects, from highways and bridges to power plants.

A robust production capacity is vital for maintaining profitability and market competitiveness. This capacity, in turn, dictates the facility's employment levels, influencing local economies and potentially regional development. Increased production often leads to economies of scale, enabling the facility to reduce production costs per unit, thus increasing its overall efficiency and ability to offer competitive prices. Conversely, a limited production capacity can restrict the facility's ability to meet market demand, potentially leading to lost revenue and market share.

Understanding the production capacity of Usiminas Ipatinga is crucial for analyzing its influence on the wider economy. The facility's output directly affects the supply chain, impacting related industries and ultimately influencing consumer prices. Sustained high production capacity, coupled with a focus on efficiency and product quality, is fundamental to Usiminas Ipatinga's continued success and relevance in a competitive global marketplace. Challenges such as fluctuating raw material costs and market demand necessitate continuous optimization strategies to ensure that production capacity remains responsive and efficient.

2. Steel Variety

The range of steel products produced at Usiminas Ipatinga is a critical factor in its economic success and market position. Diverse steel grades cater to various industrial sectors, highlighting the facility's adaptability and economic impact.

- Specific Grades for Specific Needs

Usiminas Ipatinga produces a spectrum of steel grades, each tailored to distinct industrial requirements. This includes high-strength steels for automotive components, reinforcing bars for construction, and specialized steels for machinery manufacturing. The ability to produce varied grades signifies a focus on meeting specific customer demands, enhancing market competitiveness and adaptability to evolving industry needs. For example, the presence of high-strength steel alloys allows the facility to contribute to the production of vehicles requiring superior structural integrity. Likewise, the supply of different grades supports various construction projects, ensuring structures meet safety and performance standards.

- Meeting Diverse Market Demands

The production of various steel grades directly addresses the diverse needs of multiple industries within and beyond Brazil. This adaptability allows the company to capitalize on diverse market opportunities, potentially generating greater revenue streams. By supplying various steel types, Usiminas Ipatinga fosters robust partnerships with key players across industries. This diverse production demonstrates a commitment to meeting market demands, which is critical for long-term success and sustained growth.

- Technological Advancement and Quality Control

Producing a wide range of steel grades necessitates advanced metallurgical processes and rigorous quality control measures. Maintaining consistent quality across diverse steel products is crucial to establishing a reputation for reliability and competence. This technological focus allows Usiminas Ipatinga to offer a high-quality steel product portfolio to its clients.

- Economic Implications of Variety

The ability to produce different steel grades enhances the economic value of Usiminas Ipatinga. By catering to a wider spectrum of industries and consumers, the facility secures a stronger market position. This also supports a diversified supply chain, connecting the steel mill to a broader network of related businesses. The economic impact extends beyond direct employment, influencing ancillary industries and generating related economic activity.

The variety of steel produced at Usiminas Ipatinga is not merely a feature but a strategic advantage. It reflects the facility's commitment to meeting diverse market needs, improving its economic viability, and establishing a leading position within the Brazilian steel sector. Furthermore, this demonstrates the importance of understanding and reacting to the evolving requirements of the diverse industrial base the facility serves. Maintaining this range of production and quality control is critical for Usiminas Ipatinga to remain a significant force in the Brazilian economy.

3. Employment Creation

Usiminas Ipatinga, as a significant steel producer, directly influences employment levels in the region. The scale of its operations necessitates a substantial workforce, encompassing various roles from direct production to support services. Analyzing the employment impact provides insight into the facility's role in community and regional development.

- Direct Employment Generation

The steel mill directly employs a large workforce, including operators, technicians, engineers, and support staff. The number of direct employees often correlates with production levels and facility size. This creates a substantial labor pool within the local community, with job opportunities ranging from entry-level to specialized positions requiring advanced skills.

- Indirect Employment Opportunities

Usiminas Ipatinga's operations also stimulate indirect employment in surrounding areas. Suppliers of raw materials, components, and services rely on the steel mill's activity to maintain their own businesses. This indirect employment extends the positive economic effect beyond the facility's immediate workforce, fostering interconnectedness within the regional economy.

- Skill Development and Training

The demands of modern steel production necessitate ongoing training and skill development within the workforce. This emphasis on upskilling creates a more qualified and productive labor pool, increasing the value of employees and potentially drawing further investment into the region. Specialized training programs offered by the facility or collaborations with educational institutions enhance the skills of the local workforce.

- Impact on Local Wages and Income

The presence of Usiminas Ipatinga often leads to increased wages and a higher standard of living in the surrounding community. The competitiveness of wages often influences economic trends in the region, potentially attracting skilled workers and influencing the cost of living. A reliable source of employment can lead to greater stability and income growth within the local economy.

In conclusion, Usiminas Ipatinga's employment impact extends far beyond the facility itself. The direct and indirect job creation, skill development opportunities, and influence on local wages contribute to the overall economic well-being of the region. This multifaceted impact demonstrates the interconnectedness between industrial operations and regional development.

4. Infrastructure Support

The relationship between Usiminas Ipatinga and infrastructure support is fundamental. The steel mill's operations are intrinsically linked to the existing and required infrastructure. Adequate infrastructure, encompassing transportation networks, energy supply, and communication systems, is essential for the mill's efficient functioning. A robust infrastructure supports raw material transport, finished goods distribution, and overall operational efficiency. Without dependable infrastructure, the mill's production capacity is severely limited, impacting its ability to serve market demands and fulfill its economic role.

Consider the following examples: Reliable rail lines are critical for transporting iron ore, a major raw material for steel production. Efficient port facilities facilitate the import of necessary materials and the export of finished steel products. A stable energy supply, possibly sourced from a grid or dedicated power plants, is crucial for powering the manufacturing processes. Effective communication systems are needed for coordinating operations, managing logistics, and maintaining contact with stakeholders. The lack of any of these components can create bottlenecks and lead to significant operational inefficiencies, which can impact the mill's production costs, delivery times, and overall profitability. A project's success relies on the suitability of infrastructure to handle the specific demands. For instance, an expansion in production volume might necessitate upgrades to the local transportation network to handle increased freight. Conversely, inadequate infrastructure could hinder the mill's ability to capitalize on emerging market opportunities.

In summary, infrastructure support is not merely a supporting element of Usiminas Ipatinga; it is a critical component of the mill's overall operational effectiveness and economic viability. Understanding the interconnectedness between the facility's operations and the surrounding infrastructure is essential for evaluating the long-term sustainability and potential expansion of the steel mill. Failure to consider the quality and capacity of the supporting infrastructure could lead to unforeseen challenges, impacting the mill's productivity, cost-effectiveness, and competitiveness within the steel market. Planning for and investing in appropriate infrastructure enhancements is vital for the continued success and expansion of Usiminas Ipatinga and the related Brazilian industrial landscape.

5. Economic Growth

Usiminas Ipatinga's operations are deeply intertwined with regional and national economic growth. The facility's scale and impact on various sectors create a complex web of cause-and-effect relationships. The steel mill's success fosters economic growth through direct employment, investment attraction, and the supply of crucial materials for diverse industries. This direct impact is exemplified by job creation, which not only provides livelihoods but also circulates income within local communities. The ripple effect is further amplified through the stimulation of related industries like construction, transportation, and manufacturing, creating a cascading effect that propels economic development.

The importance of economic growth as a component of Usiminas Ipatinga is paramount. A thriving regional economy provides a stable environment for the facility's operations. Increased economic activity generates demand for steel products, which in turn necessitates higher production levels. This necessitates further investment in the mill, leading to technological advancements and improved efficiency. A positive feedback loop emerges, where economic prosperity and industrial strength reinforce one another. Conversely, downturns in the broader economy can directly influence Usiminas Ipatinga's performance. Lower demand for steel leads to reduced production, affecting employment, investment, and the overall economic health of the region. For instance, a robust construction sector experiencing rapid expansion will generate a higher demand for steel products from the mill, directly correlating with economic growth. Conversely, decreased activity in the construction sector will negatively impact the mill's production levels, illustrating the direct correlation between economic activity and steel demand.

In conclusion, the link between economic growth and Usiminas Ipatinga is demonstrably significant. The facility's operations are not isolated but represent a vital part of the regional and national economic landscape. Understanding this intricate relationship is crucial for strategic planning and development. Maintaining a robust and sustainable economic environment is crucial for the long-term viability and prosperity of both the steel mill and the wider community it serves. Future projections of economic growth should incorporate the expected performance of the steel mill and its various interactions with the broader industrial sector, highlighting the importance of consistent and calculated economic growth as a key driver for continued success for both the facility and the wider economy. The ability to foresee and adapt to economic shifts is key for sustained prosperity.

6. Environmental Impact

Usiminas Ipatinga's environmental impact is a crucial aspect of its operations. Steel production, by its nature, involves resource consumption and potential environmental consequences. The scale of this activity demands careful consideration of waste management, emissions, and resource depletion. A thorough understanding of these factors is fundamental to the facility's long-term sustainability and the protection of surrounding ecosystems. Failure to address environmental concerns can lead to reputational damage, legal penalties, and the degradation of local environments.

The environmental impact manifests in several ways. Emissions from the facility, including particulate matter and greenhouse gases, contribute to air pollution. Wastewater discharge, if not properly treated, can contaminate water sources. Resource consumption, such as water and raw materials like iron ore, requires careful management to avoid depletion and habitat destruction. Land use for the facility and associated infrastructure can also impact ecosystems. For example, deforestation for the expansion of mining operations or industrial areas represents a considerable environmental concern. The management of tailings from iron ore processing requires careful planning to prevent water contamination. Real-world examples, such as incidents of water pollution or air quality violations, illustrate the tangible consequences of inadequate environmental oversight. A facility's response to and mitigation of these environmental challenges, therefore, directly impacts the well-being of the surrounding communities and ecosystems. Furthermore, compliance with environmental regulations and adherence to best practices contribute to a positive public image and sustainable development.

Understanding the environmental impact of Usiminas Ipatinga is essential for assessing the facility's broader societal contribution. Sustainable practices minimize environmental risks and foster a responsible approach to resource management. The adoption of clean technologies, coupled with careful waste management protocols, reduces the facility's environmental footprint. The implementation of environmental impact assessments, followed by preventative measures and continuous monitoring, minimizes potential ecological harm. Successfully mitigating the environmental impact is not merely a legal requirement; its a critical factor for sustained community support, long-term economic viability, and a positive corporate image. A proactive approach to environmental stewardship, integrating environmental concerns into every aspect of operation, strengthens the facility's resilience and long-term sustainability.

7. Global Market Presence

Usiminas Ipatinga's global market presence is a critical component of its overall success. The steel mill's ability to access and compete in global markets directly impacts its profitability, strategic positioning, and overall economic significance. A significant global presence indicates the mill's ability to meet international demand, access diverse raw material sources, and leverage advantageous pricing opportunities. This requires not just production capacity but also effective export strategies, distribution networks, and adherence to international quality standards.

Real-world examples illustrate the practical significance of this understanding. A global market presence allows Usiminas Ipatinga to access raw materials like iron ore from various sources, potentially securing more favorable supply contracts. It facilitates access to a broader customer base, reducing dependence on a single market or region. Conversely, a limited global presence might constrain the mill's ability to respond to fluctuations in local markets, potentially impacting profitability and growth. For instance, high demand in one region could lead to a significant increase in steel prices, whereas low demand in another region might force the company to seek alternative markets and contracts. Successfully navigating these global market dynamics is crucial for Usiminas Ipatinga's continued growth and long-term sustainability.

In summary, Usiminas Ipatinga's global market presence is not just a desirable feature but a fundamental element of its strategic positioning and financial performance. The facility's ability to operate effectively within a global context influences not only its own success but also contributes to broader economic activity. Challenges such as fluctuating exchange rates, import regulations, and differing customer preferences need to be carefully considered. A deep understanding of these intricacies is essential for the facility to maximize opportunities and mitigate potential risks in the complex global steel market.

Frequently Asked Questions about Usiminas Ipatinga

This section addresses common inquiries regarding Usiminas Ipatinga, a significant steel production facility in Ipatinga, Brazil. These answers aim to provide clarity and factual information.

Question 1: What is the primary function of Usiminas Ipatinga?

Usiminas Ipatinga is a large-scale steel mill. Its core function is the production and processing of various steel types, serving a broad range of industries. This encompasses raw material processing, steelmaking, and the subsequent production of finished steel products.

Question 2: What is the economic impact of Usiminas Ipatinga on the region?

The steel mill's operations generate substantial direct employment, influencing local wages and income. The facility's activities also stimulate indirect economic activity through related industries such as construction, transportation, and manufacturing, fostering overall regional economic growth.

Question 3: How does Usiminas Ipatinga manage its environmental impact?

Environmental considerations are integral to Usiminas Ipatinga's operations. The facility employs various strategies, including waste management programs, emission control technologies, and adherence to environmental regulations. This commitment to minimizing environmental impact is vital for the facility's long-term sustainability.

Question 4: What types of steel products does Usiminas Ipatinga produce?

The facility produces a diverse range of steel products, tailored to various industrial needs. This includes specialized steel grades for automotive components, construction materials, and machinery manufacturing, highlighting the mill's adaptability to diverse market demands.

Question 5: What is Usiminas Ipatinga's role in the global steel market?

Usiminas Ipatinga participates in the global steel market, exporting products to various countries. Its global presence underscores its competitive capabilities, market reach, and contribution to international trade.

These frequently asked questions provide a concise overview of Usiminas Ipatinga's operational scope, economic significance, and environmental considerations. Further research may provide more detailed information.

The following sections will delve deeper into the specific processes, challenges, and future prospects of Usiminas Ipatinga.

Conclusion

Usiminas Ipatinga stands as a pivotal component of Brazil's industrial landscape. This analysis underscores the multifaceted nature of its impact. Key findings reveal the facility's substantial production capacity, diverse product portfolio, significant employment creation, and essential infrastructure support. The facility's role in regional economic growth is evident, as is its connection to national infrastructure projects. However, the environmental impact of steel production, particularly at this scale, warrants ongoing attention. Maintaining a delicate balance between economic growth and environmental sustainability is crucial for long-term viability.

Usiminas Ipatinga's future success hinges on its ability to navigate global market fluctuations while adhering to stringent environmental standards. Continued investment in technological advancements and sustainable practices will be paramount. The facility's sustained contribution to the Brazilian economy, regional development, and the broader global steel market necessitates proactive measures to anticipate and respond to evolving challenges. Further analysis should explore specific strategies for enhancing environmental performance and optimizing production efficiency to maximize long-term benefits for all stakeholders.

Detail Author:

- Name : Prof. Athena Blick

- Username : alphonso34

- Email : lorn@spencer.com

- Birthdate : 2000-10-02

- Address : 2775 Nader Fall Suite 184 East Kassandra, HI 38263-2850

- Phone : 352-394-4952

- Company : Hintz-Koelpin

- Job : Adjustment Clerk

- Bio : Rerum rerum alias quia optio. Sit et sint unde qui earum. Quisquam magnam officiis ducimus eaque.

Socials

twitter:

- url : https://twitter.com/nicolasg

- username : nicolasg

- bio : Et ut eveniet dolores. Accusamus delectus cum iste reprehenderit. Odio doloribus fuga nobis.

- followers : 5815

- following : 468

facebook:

- url : https://facebook.com/golden_nicolas

- username : golden_nicolas

- bio : Quis laudantium consequuntur dignissimos quia at iure quidem suscipit.

- followers : 4811

- following : 1505