What are the properties and applications of this fundamental chemical compound?

A seemingly simple substance, this particular gaseous substance lacks visible color. It's a common component in various industries and often crucial for a range of processes. This gas can exist in either a compressed or liquefied form, depending on the specific application. For instance, it's frequently used in specialized manufacturing techniques or as an essential element in refrigeration systems.

The importance of this transparent gas extends across diverse sectors. In industrial settings, it's a valuable reactant in many chemical processes. Its inert nature makes it suitable for creating controlled environments where other reactions might be compromised by competing components. In scientific contexts, its controlled introduction to systems allows researchers to observe and manipulate processes under precisely defined conditions. Its historical significance stems from its critical role in early industrial revolutions and continues to hold prominence in advanced technologies today.

Let's delve into specific examples of the uses of this colorless gas, highlighting its critical role in modern life.

Colorless Gas

Understanding the properties and applications of colorless gases is crucial for various scientific and industrial processes. Their diverse roles underscore their importance in modern life.

- Chemical inertness

- Low reactivity

- Wide applications

- Compressed storage

- Liquefaction potential

- Manufacturing processes

- Food preservation

- Scientific research

These aspects, taken together, highlight the versatile nature of colorless gases. Chemical inertness allows their use as protective atmospheres in manufacturing, while low reactivity makes them suitable for various food preservation methods. Their compressed and liquefied forms facilitate efficient storage and transportation, crucial for widespread industrial applications. Examples include nitrogen in food packaging, argon in welding, and helium in cryogenic systems. These characteristics, coupled with their abundance and ease of processing, underscore their significant contributions across a broad spectrum of industries.

1. Chemical Inertness

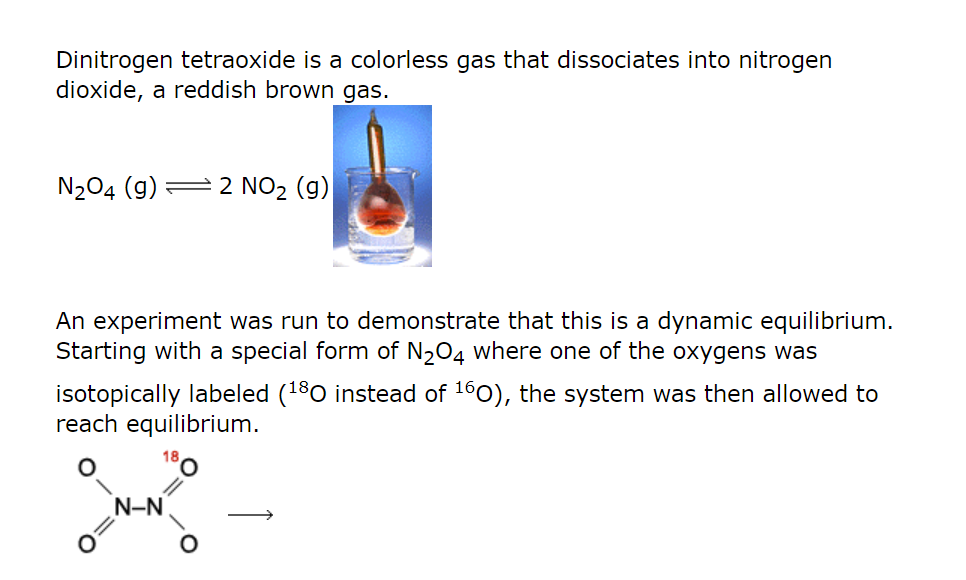

The characteristic of chemical inertness, crucial to many applications involving colorless gases, arises from the nature of their molecular structure and the resulting lack of reactivity. This property is fundamental to their utility in various industrial and scientific contexts.

- Lack of Reactivity in Chemical Reactions

Inert gases, often colorless, possess stable electron configurations. This stability minimizes their tendency to participate in chemical reactions. They do not readily combine with other elements under typical conditions, providing a controlled environment for other reactions to proceed without interference.

- Controlled Environments in Manufacturing

Industries utilize this inertness in various manufacturing processes. For example, nitrogen is frequently employed to create an inert atmosphere that prevents oxidation or unwanted reactions. This is vital for metal working and in maintaining consistent quality.

- Protective Atmosphere in Food Preservation

The inert nature of these gases also allows them to be used in food packaging. Maintaining a sealed environment with an inert atmosphere, often nitrogen, prevents oxidation and microbial growth, ensuring longer shelf life for products. This protective function is key to the preservation of food.

- Applications in Scientific Research

In scientific contexts, the lack of reactivity of inert gases allows for precision and control in experiments. They create stable environments crucial in many research areas, including chemistry, physics, and materials science.

In summary, the chemical inertness of colorless gases underpins their widespread applications. Their stability and lack of reactivity allow for controlled environments vital in manufacturing, preservation, and scientific research. This makes these gases essential components in a diverse array of processes.

2. Low Reactivity

Low reactivity is a defining characteristic of many colorless gases, significantly impacting their applications and utility. This property arises from the electronic structure and stability of the gaseous molecules, influencing their interactions with other substances.

- Stability of Molecular Structure

Many colorless gases exhibit stable electronic configurations. This stability minimizes their tendency to participate in chemical reactions, leading to low reactivity. Atoms or molecules in such a configuration require significant energy input to engage in bonding or rearrangements.

- Inertness in Chemical Reactions

The low reactivity of these gases translates directly to their inertness in chemical reactions. This inertness allows them to serve as protective atmospheres in industrial processes, preventing unwanted side reactions. For instance, nitrogen's use in food packaging maintains product freshness by inhibiting oxidation.

- Controlled Environments for Reactions

By virtue of their low reactivity, colorless gases enable the creation of controlled environments for other chemical reactions. This is vital in industrial settings where minimizing interference is crucial for product quality. Argon, for example, is often employed in welding to prevent oxidation of the metal.

- Practical Applications in Manufacturing and Science

The low reactivity of colorless gases underpins various applications. Their use extends from manufacturing processes that require a stable atmosphere to scientific experiments that necessitate a controlled environment free from extraneous reactions. This control allows for precision and accuracy in these settings.

In conclusion, the low reactivity of many colorless gases is a critical factor in their widespread use. This property underpins their ability to serve as protective atmospheres, control reactions, and enable precise experiments. The inert nature of these gases makes them essential in various industrial and scientific contexts.

3. Wide Applications

The broad spectrum of applications for colorless gases stems directly from their fundamental properties. The lack of reactivity, coupled with inherent stability and often readily available form, creates a wide range of potential uses. These gases function as inert atmospheres, shielding materials from unwanted chemical reactions, as well as carriers for other substances. The ability to control atmospheres for various industrial processes, from manufacturing to preservation, is a direct consequence of these properties. This allows for precise control, contributing to efficiency and product quality.

Consider the widespread use of nitrogen in food packaging. The inertness of nitrogen prevents oxidation and spoilage, extending the shelf life of various products. Similarly, argon is employed in welding to create an inert atmosphere, protecting the metal from oxidation during the process. In cryogenic applications, helium's low boiling point allows for the creation of extremely low temperatures. These examples highlight the wide-ranging impact of colorless gases in industries as diverse as food processing, metallurgy, and scientific research. The controlled introduction of these gases often ensures that processes function according to specifications, and maintain desired outcome levels, making them essential components in modern manufacturing practices.

The connection between the broad applications of colorless gases and their fundamental properties, particularly inertness, is demonstrably clear. This fundamental understanding guides the strategic use of these gases in various industrial contexts, allowing for precision control in processes. Understanding these principles underpins the efficient application of these gases, ensuring quality control and optimal results. Further investigation into the specific properties of individual colorless gases will illuminate their particular roles in various applications, enhancing our appreciation for their crucial contributions.

4. Compressed Storage

Compressed storage is a critical component in the practical application of many colorless gases. The inherent properties of these gases, particularly their low densities in the gaseous state, necessitate specialized storage methods to maintain a manageable volume. Compression significantly reduces the volume occupied by a given mass of colorless gas, allowing for economical and safe transport and storage within limited spaces. This process is essential for ensuring accessibility and usability in various industrial and scientific settings. Consequently, efficient storage is pivotal to the widespread use of colorless gases.

The practicality of compressed storage hinges on the ability to maintain pressure within sealed containers. Specific materials and design considerations are crucial to ensure safety and structural integrity. Failures in these systems, such as leaks or ruptures, can pose significant risks, highlighting the importance of rigorous safety protocols and well-maintained equipment. Real-world examples include the pressurized cylinders used for oxygen, nitrogen, and other gases in medical, industrial, and research settings. The ability to compress these gases allows their concentrated distribution to remote or inaccessible locations. Moreover, compressed storage enables the integration of these gases into various industrial processes, maximizing their utilization.

In conclusion, compressed storage is integral to the widespread applications of colorless gases. The ability to concentrate these gases into manageable volumes significantly facilitates their transport, storage, and utilization in diverse industries. Understanding the underlying principles of pressure containment and appropriate storage techniques is crucial for ensuring both efficiency and safety. Challenges associated with compressed gas storage include maintaining structural integrity and preventing leaks. The practical benefits of compressed storage extend far beyond mere convenience; they are essential for the effective and safe incorporation of colorless gases into a wide range of applications.

5. Liquefaction Potential

The liquefaction potential of a colorless gas is a critical property influencing its practicality and widespread applications. Liquefaction, the process of converting a gas into a liquid state, alters the substance's characteristics, often significantly enhancing its storage, transport, and application versatility. Gases with a high liquefaction potential are more readily condensed into liquids under suitable pressure and temperature conditions. This property is pivotal because liquid form allows for more efficient storage and transport, often reducing the volume occupied by a given mass, compared to the gaseous state. This translates into economic benefits and logistical advantages.

Several colorless gases exhibit high liquefaction potentials, enabling their use in diverse sectors. Refrigeration systems, for example, rely heavily on substances with precisely controlled liquefaction points. The ability to efficiently liquefy and vaporize refrigerants allows for precise temperature control. Similarly, industries employing these gases in specialized processes utilize their liquefied forms for efficient transport and handling. The storage and utilization of liquefied natural gas (LNG) exemplify this principle, where the volume reduction afforded by liquefaction significantly reduces transportation costs and environmental footprint. Further examples include the use of liquefied oxygen, nitrogen, and argon in various industrial and scientific applications, emphasizing the significant role of liquefaction in enabling these applications.

The liquefaction potential of a colorless gas is inextricably linked to its fundamental properties, such as intermolecular forces and critical temperature. Understanding these relationships allows for optimized storage and transportation strategies, while enabling precise control in processes utilizing these substances. The efficient and safe liquefaction and vaporization of these gases are essential for minimizing safety risks and maximizing operational efficiency. Challenges remain in the development of highly efficient and cost-effective liquefaction technologies for certain gases. Continued research and development in this area are necessary to optimize the application of colorless gases with high liquefaction potentials across diverse industrial and scientific domains.

6. Manufacturing Processes

Colorless gases play a critical role in numerous manufacturing processes, acting as essential components in creating controlled environments, facilitating reactions, and enhancing product quality. The precise control of atmospheres, often achieved through the introduction of specific colorless gases, is vital in various industrial settings. This control directly impacts the efficiency and safety of operations, influencing the quality and consistency of manufactured goods. The understanding of how these gases interact within manufacturing processes is essential for optimizing production and mitigating risks.

Specific examples illustrate the profound impact of colorless gases in manufacturing. In metal fabrication, inert gases like nitrogen or argon prevent oxidation, ensuring the integrity and quality of the final product. This protection minimizes material degradation and enhances the structural soundness of the manufactured items. In semiconductor manufacturing, precise control over the gaseous environment is crucial for crystal growth and chip fabrication. The introduction of specific gases enables controlled deposition and reduces contamination, ensuring the desired properties and reliability of integrated circuits. In polymer processing, controlled atmospheres with nitrogen are necessary to prevent unwanted reactions and ensure consistent product properties. These examples highlight the critical connection between specific colorless gases and optimized manufacturing outcomes.

In conclusion, the intricate relationship between manufacturing processes and colorless gases is multifaceted. The precise control achieved through these gases is fundamental to maintaining product quality, promoting efficiency, and enhancing safety in manufacturing facilities. Understanding and applying this knowledge are paramount in maximizing production outputs and ensuring the reliability of manufactured goods. Future advancements in this area will undoubtedly lead to even more precise control and greater efficiency in diverse manufacturing applications.

7. Food Preservation

The preservation of food relies heavily on controlled environments, and colorless gases play a pivotal role in this process. Inert atmospheres, often created using nitrogen or carbon dioxide, are employed to mitigate oxidation, microbial growth, and enzymatic activity, thereby extending the shelf life of various food products. This method ensures the maintenance of food quality and safety over prolonged periods, ultimately benefiting consumers and the food industry.

Specific applications showcase the significance of this approach. Nitrogen, for example, displaces oxygen in packaging, preventing the oxidative degradation of fats, proteins, and vitamins. This extends the freshness and nutritional value of products like meat, poultry, and baked goods. Carbon dioxide, another colorless gas, inhibits the growth of certain microorganisms, hindering spoilage and maintaining the integrity of foods like fruits and vegetables. The effectiveness of these techniques is demonstrated through the extended shelf life of processed foods, pre-packaged meals, and fresh produce, showcasing the substantial impact of colorless gases on the food supply chain.

In summary, the use of colorless gases in food preservation is critical for safeguarding the quality and safety of food products. Maintaining a controlled atmosphere inhibits the undesirable reactions leading to spoilage, thereby extending shelf life and contributing to the sustainability of the food industry. The effectiveness of this method, supported by numerous real-world applications, underscores its importance in modern food production and distribution. However, the precise selection of gases and optimal packaging strategies are essential to ensure both preservation and product quality remain optimized throughout the supply chain.

8. Scientific Research

Scientific research frequently utilizes colorless gases due to their specific properties, enabling controlled experiments and precise observations. Their inertness, lack of reactivity under certain conditions, and manageable manipulation in various states (gas, liquid, solid) make them invaluable tools for researchers in diverse fields.

- Controlled Environments for Reactions

Many scientific investigations require controlled environments where extraneous reactions are minimized. Colorless gases, notably inert ones like nitrogen and argon, create these environments. These gases are introduced into reaction chambers to displace reactive elements or provide an inert atmosphere, allowing researchers to study specific chemical processes without interference. This is particularly vital in chemistry, material science, and other related disciplines.

- Precise Measurement and Analysis

Colorless gases facilitate precise measurements in various scientific instruments. Their stable properties and predictable behavior enable researchers to calibrate and utilize equipment for accurate analysis. For instance, the use of helium in gas chromatography allows for precise separation and identification of components in complex mixtures. Specific isotopes of colorless gases also play a role in precise dating methods, highlighting their application across varied scientific fields.

- Modeling and Simulation of Processes

Researchers model and simulate various processes involving colorless gases. By carefully controlling the introduction, manipulation, and interaction of these gases, scientists can develop accurate models and simulations. This is vital for understanding phenomena such as atmospheric processes, reaction kinetics, and gas behavior in specialized environments, such as those found in outer space or at extreme pressures. Advanced analytical techniques leverage the predictable behavior of colorless gases to improve simulation accuracy and detail.

- Study of Gas Properties and Interactions

Scientific research delves into the fundamental properties of colorless gases themselves. Investigations explore interactions between gases, their behavior under varying conditions (temperature, pressure), and their impact on other substances. This knowledge is vital for advancements in engineering, physics, and material science. Advanced techniques such as spectroscopic analysis and complex computational models help in elucidating the subtle interactions within these gaseous systems.

In conclusion, the fundamental properties of colorless gases, particularly their inertness and predictable behavior, underpins their crucial role in diverse scientific research domains. From creating controlled environments for chemical reactions to analyzing gas behavior in advanced technologies, the applications are extensive. Further research into these gases often reveals novel insights and pushes the boundaries of scientific understanding across numerous disciplines.

Frequently Asked Questions about Colorless Gases

This section addresses common inquiries regarding colorless gases, focusing on their properties, applications, and safety considerations.

Question 1: What distinguishes colorless gases from other gases?

Colorless gases are characterized by their lack of visible color. This property, while seemingly simple, is significant in differentiating them for specific applications. The lack of color does not inherently dictate other properties; their chemical reactivity, density, and liquefaction points vary significantly. The key distinction lies in the visual characteristic, not inherent chemical composition.

Question 2: What are some common examples of colorless gases?

Several common colorless gases include nitrogen, oxygen, argon, and carbon dioxide. These are frequently encountered in industrial processes, scientific research, and everyday life, highlighting the prevalence of such substances.

Question 3: How are colorless gases stored and transported safely?

Storage and transport protocols for colorless gases are rigorously standardized due to the potential risks associated with compressed or liquefied states. Specific containers, pressure regulations, and handling procedures are employed to minimize hazards. Safe practices adhere to established industry standards to prevent accidents and ensure proper containment.

Question 4: What are the various applications of colorless gases in industry?

Colorless gases find applications across diverse industrial sectors. Nitrogen, for example, serves as an inert atmosphere in various manufacturing processes, while argon is crucial in welding. Carbon dioxide has a crucial role in food preservation. The specific application hinges on the particular properties of the gas and the requirements of the process.

Question 5: Are there environmental concerns associated with the use of colorless gases?

Certain colorless gases, like carbon dioxide, are associated with environmental concerns due to their impact on the atmosphere. The use of these gases must be considered in the context of sustainability and appropriate emissions controls. Responsible practices and ongoing research aim to mitigate potential environmental impacts.

Understanding the properties and applications of colorless gases is crucial for safe and efficient utilization across various sectors. Further study of specific gases is essential for targeted applications and environmental considerations.

Next, we will explore the specific chemical and physical properties of individual colorless gases, deepening our understanding of their behaviors and roles.

Conclusion

This exploration of colorless gases reveals their multifaceted roles across various sectors. The fundamental properties of inertness, low reactivity, and diverse liquefaction potentials underpin their extensive applications. From maintaining controlled environments in manufacturing to extending food shelf life and enabling precise scientific research, the impact of colorless gases is profound. The ability to compress and liquefy these gases significantly enhances their usability, facilitating storage, transport, and application in specialized industrial and scientific processes.

The significance of colorless gases extends beyond their current applications. Continued research into their specific properties and behaviors holds the potential for further innovation in areas like advanced materials, energy storage, and environmental technologies. Understanding the intricate relationships between the properties of these gases and their practical applications is crucial for developing more efficient, safe, and sustainable processes in the future. A deeper comprehension of the diverse roles played by these fundamental substances will undoubtedly contribute to advancements across numerous scientific and industrial fields.

Detail Author:

- Name : Rogelio Hartmann I

- Username : vconroy

- Email : kyle64@yahoo.com

- Birthdate : 2000-05-16

- Address : 641 Kub Valleys Apt. 290 New Tatum, TN 26037-1547

- Phone : +1 (551) 534-8064

- Company : Runolfsson-Lockman

- Job : Environmental Engineer

- Bio : Blanditiis sit natus tenetur ut explicabo quo error eum. Dolore quia facilis nulla voluptate. Et deserunt sed et voluptatum. Vel illum eligendi et blanditiis eos distinctio cum.

Socials

twitter:

- url : https://twitter.com/kylee.luettgen

- username : kylee.luettgen

- bio : Velit velit est aut libero ut qui. Quo vel accusantium sint maiores quos qui. Placeat quia harum qui animi.

- followers : 3830

- following : 590

facebook:

- url : https://facebook.com/kylee7954

- username : kylee7954

- bio : Totam consequatur et accusamus. Nihil necessitatibus doloribus deserunt nam.

- followers : 6378

- following : 955

instagram:

- url : https://instagram.com/kylee.luettgen

- username : kylee.luettgen

- bio : At suscipit illo sint et quia. Itaque pariatur ullam omnis possimus voluptatum est.

- followers : 4376

- following : 1008

tiktok:

- url : https://tiktok.com/@kyleeluettgen

- username : kyleeluettgen

- bio : Quod non necessitatibus veritatis beatae ullam et ratione error.

- followers : 2689

- following : 917

linkedin:

- url : https://linkedin.com/in/kyleeluettgen

- username : kyleeluettgen

- bio : Qui quo aliquid molestiae aut.

- followers : 2003

- following : 2041